High Temperature Heat Pumps

Energy demand in industrial applications is a significant percentage of the total energy demand which is still dependent on fossil fuels. Heat in industry accounts for 74% of industrial energy demand and almost 20% of global energy consumption. The development and application of high temperature heat recovery technologies, such as high temperature heat pumps, can provide high efficiency heat supply that meets the heat demand of industry, leading to reduced operating costs and CO2 emissions.

Large amounts of process heat are rejected

Recovery of low-temperature range: 40 – 90 °C

Upgrade up to 120 °C steam or pressurized water

Covering heating needs or thermal processes

Heating capacity: 100 kWth – 1.5 MWth

COP: 2.5 – 4 depending on the source/sink conditions

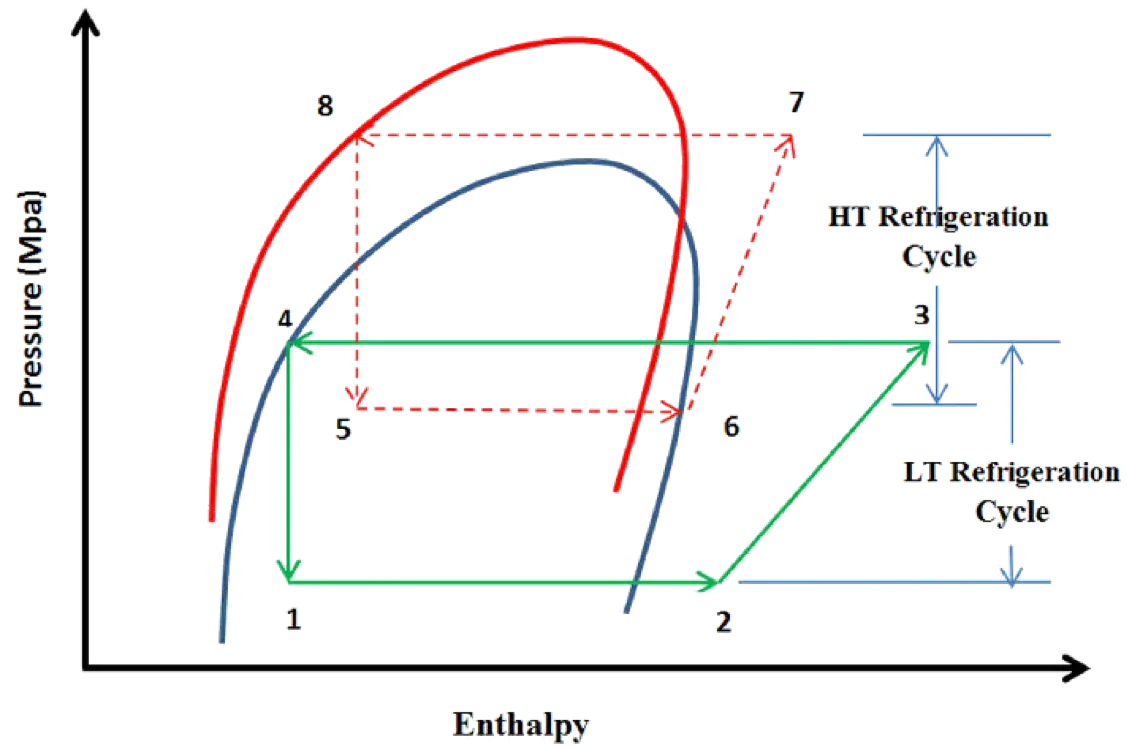

How it works

ThermoDraft manufactures high temperature (up to 120°C) heat pumps and capacities varying from 100 to 1500 kW for upgrading heat in industrial processes. The refrigerant used belongs to the group of the newly developed hydrofluoroolefins (HFOs) which are characterized by a very low GWP (<10).

Conventional and new-generation eco-friendly refrigerants with negligible GWP and Ozone Depletion potential (ODP) may be employed, such as R1234ze(E) or R1233zd(E). Polyester oil (POE) with appropriate viscosity and compatible with the refrigerants is used for the lubrication of the compressor, which operates at high temperatures.

Heat rejected from a process is used to evaporate a refrigerant.

The refrigerant is compressed and then is cooled, releasing usable heat at 100-120°C, generating steam or pressurized hot water.

Refrigerant suitable for the temperature range is selected.

Main components

High-Temperature Screw Compressor

Condenser & Evaporator: Shell and Tube or PHE

Oil Separator – Oil cooler

Specialized materials of heat exchangers for special applications

1 or 2 circuits depending on the application

Can be combined with an MVR for higher temperatures/pressures of steam.

Applications

Models

ThermoDraft manufactures high temperature heat pumps for heat source temperature range 40-90 °C and heat sink temperature up to 120 °C. The heating capacity lies within the range of 100 kW to 1.5 MW, with a COP up to 4.

Medium temperature for up to 90°C hot water

Refrigerant: R1234ze(E)

| 1 COMPRESSOR SERIES | 2 COMPRESSORS SERIES | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | 100G | 230G | 410G | 470G | 710G | 790G | 2.100G | 2.230G | 2.410G | 2.470G | 2.710G | 2.790G |

| Nominal heating capacity (kW) | 104 | 258.7 | 433.7 | 492.9 | 744.7 | 820.7 | 208 | 517.4 | 867.4 | 985.8 | 1489.4 | 1641.4 |

| Power consumption (kWe) | 36.3 | 84.3 | 136.4 | 154.1 | 229.9 | 249.4 | 72.6 | 168.6 | 272.8 | 308.2 | 459.8 | 498.8 |

The above mentioned performance is for 35°C cooling water from renewables (e.g. solar) or waste heat recovery (e.g. from waste water, refrigeration unit condenser). Hot supply: 70/80°C hot water in/out. Limits: 90°C maximum hot water supply / 25°C minimum cooling water temperature.

High temperature for up to 120°C pressurized hot water or low-pressure steam

Refrigerant: R245fa or R1233zd(E)

| 1 COMPRESSOR SERIES | 2 COMPRESSORS SERIES | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | 200T | 300T | 410T | 550T | 620T | 710T | 830T | 930T | 2.200T | 2.300T | 2.410T | 2.550T | 2.620T | 2.710T | 2.830T | 2.930T |

| Nominal heating capacity (kW) | 113.6 | 176.5 | 248.9 | 335.4 | 378.8 | 439.6 | 521.1 | 582.4 | 227.2 | 353 | 497.8 | 670.8 | 757.6 | 879.2 | 1042.2 | 1164.8 |

| Power consumption (kWe) | 42.9 | 66.5 | 94.3 | 124.1 | 140 | 162.5 | 192.1 | 214.4 | 85.8 | 133 | 188.6 | 248.2 | 280 | 325 | 384.2 | 428.8 |

The above mentioned performance is for 60°C cooling water from renewables (e.g. solar) or waste heat recovery (e.g. from waste water, refrigeration unit condenser). Hot supply: 100/110°C in/out. Limits: 120°C maximum hot water supply / 45°C minimum cooling water temperature.